Introduction:

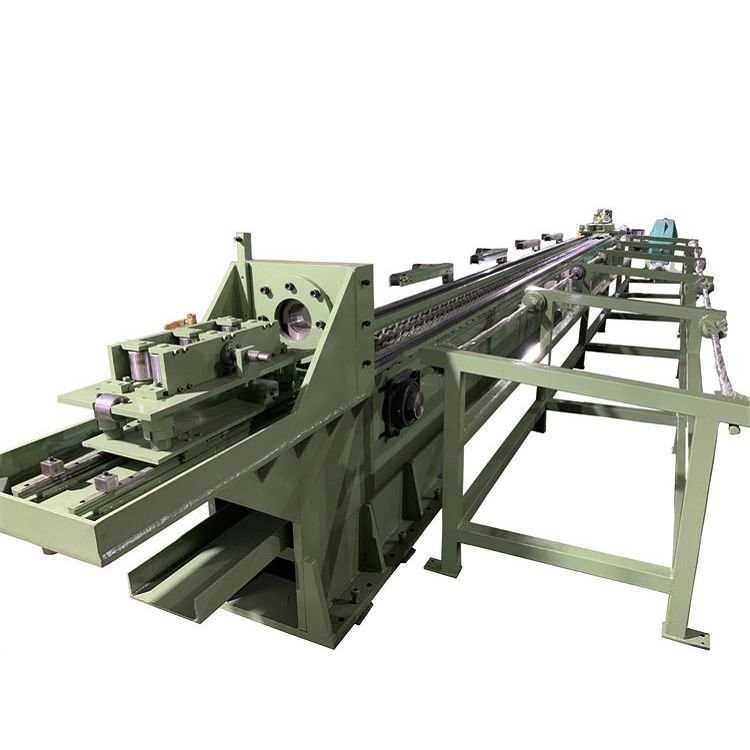

The Tube Draw Bench Machine is a high-quality machine that is designed to provide businesses with the ability to manufacture high-quality tubes at a fast and efficient rate. This machine is manufactured in China and is specifically designed for businesses that require a reliable and efficient method of tube production. With its advanced technology and superior quality, this machine has quickly become a popular choice among businesses in countries outside of China.

Features:

The Tube Draw Bench Machine offers a number of advanced features that make it an ideal solution for businesses looking to manufacture tubes. One of the key features of this machine is its ability to produce tubes with a high degree of precision. This is achieved through the use of advanced technology that ensures the tube is drawn to the exact specifications required.

Another key feature of the Tube Draw Bench Machine is its speed. This machine is capable of producing tubes at a much faster rate than other manufacturing methods, making it an ideal solution for businesses that need to produce large quantities of tubes quickly. This can help businesses save time and reduce production costs, as the machine can produce a large number of tubes in a short period of time.

Additionally, the Tube Draw Bench Machine is incredibly easy to use. Its intuitive interface and simple operating instructions make it easy for businesses to start using the machine as soon as it is delivered. This means that businesses can start producing high-quality tubes right away, without having to spend time training their employees on how to use the machine.

Advantages:

The Tube Draw Bench Machine offers a number of advantages to businesses that use it for tube manufacturing. One of the main advantages of this machine is its high degree of precision. Because the machine is able to produce tubes to exact specifications, businesses can be confident that the tubes they manufacture will meet the highest quality standards. This can help businesses establish a reputation for producing high-quality tubes that customers can rely on.

Another advantage of the Tube Draw Bench Machine is its speed. Because the machine is capable of producing tubes at a faster rate than other manufacturing methods, businesses are able to reduce their production times and increase their output. This can help businesses meet customer demand and increase their profitability in the process.

Finally, the Tube Draw Bench Machine is incredibly reliable. Because it is built to the highest quality standards, businesses can be confident that the machine will perform consistently over time. This means that businesses can rely on the machine to produce high-quality tubes day in and day out, without having to worry about equipment breakdowns or other issues that can derail production.

Conclusion:

In conclusion, the Tube Draw Bench Machine is an advanced and reliable solution for businesses that need to manufacture high-quality tubes quickly and efficiently. With its advanced technology, superior quality, and ease of use, this machine has quickly become a popular choice for businesses in countries outside of China. If you are looking to manufacture high-quality tubes, you can rely on the Tube Draw Bench Machine to help you achieve your goals.

Specification of Tube draw bench machine

Tube Draw Bench Machine | |

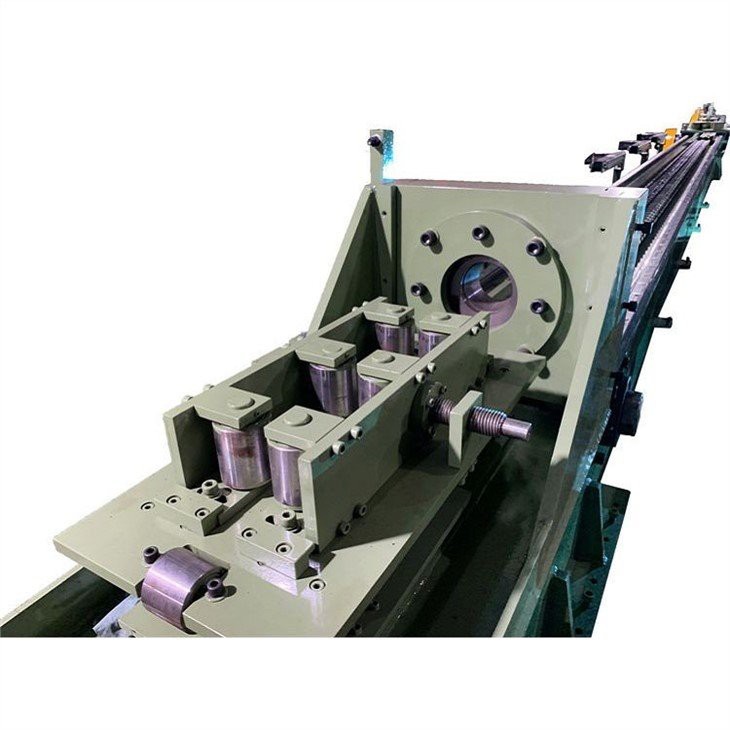

Model | FR-150 CHAIN DRAWING MACHINE |

Drawing manner | 1 line type; both sides drawing chain; middle discharging; |

Raw material tube diameter | Max.ф100mm (Different material with different diameter range, it depend on the reduction.) |

Effective length | Effective length 8m(the distance from carriage to Mold base) |

Core length | Effective length 6m |

Drawing force | 40T |

Drawing speed | 0-15m/min |

Motor | Host motor: 132kw DC speed regulator; |

Coupling | Flange glue stick type coupling |

Power and voltage | 380V 50HZ |

Frame | Front 25# H steel*4pcs; |

Chain | Host chain:4020 heaving benching plate chain; |

Sprocket shaft | Ф200mm |

Chain wheel | 18 teeth |

Mould/Dies basement | 120mm thickness |

Mould installation rack | Ball type adjustable mould base |

Pipe receiver device | Pneumatic cylinder lifts and falls to receive pipe; |

Pipe feeding device | Automatic single pipe in |

Drawing trolley | Pneumatic clamping (Clamping method |

Automatic rack | Carrying capacity<2T; |

Raw material tube straightness required | ≤2mm/m |

Raw material tube inner diameter required | ≥18mm |

Drawing oil | Pneumatic diaphragm oil pump; |

Mould/Dies | Not including |

The equipment installation drawing is supplied after two parties’ agreement. The buyer supplies the power, air power, concrete foundation, chain lubrication oil, reducer oil, drawing oil. | |

Company Profile

Dongguan Fangrong Precision Machinery Industry Co., Ltd., established in 1999, is a professional manufacturer of wire drawing machines, straightening machines, thread rolling machines and other equipment. Our company is a professional manufacturer integrating development, production and sales. Over the years, our goal is to be professional first-class equipment, first-class service, first-class innovation, and to achieve product specialization, technology specialization, service specialization, and teamwork.

CLIENT CASE

Applicable industries:

Manufacturing, Food & Beverage, Household, Retail, Energy & Mining, Food & Beverage

PACKAGE&SHIPPING

Straightening Machines Packed in plastic films in container, electrical parts must be wrapped in a waterproof package in wooden case which not defected due to sea shipment.

PRODUCTION WORKSHOP

FAQ

Q: Where is your factory located?

A: In Dongguan City, Guangdong Province China.

Q: Do you have QC department?

A: Yes,we have 6 QC persons.

Q: How your quality guarantee?

A:We have 100% quality guarantee to customers. We will be responsible for any quality problem.

Q:Would you have a discount if l have a large order?

A: Yes we could offer different discount according to your order quantity.

Q:Visiting factory is allowed or not?

A: Yes, we welcome customers visiting our factory. Our factory is located Gongyi city,Henan province,China mainland.

Q:Do you looking for Agent?

A:Yes, we're looking for the agent all over the world, please contact us for further discussion.

Q:How to solve the equipment trouble during using ?

A: Please email us about problem with pictures or a small video will be better,we will find the problem and solve it. If broken, we will send you a new free part if in the warranty period.

Why choose us?

- Our Tube Drawing Machines are available for purchase or lease, providing flexible options for your business.

- We have been pursuing high-quality, cost-effective and highly interchangeable Tube Draw Bench Machine to serve the global users.

- Our quality control measures ensure that every Tube Drawing Machine meets strict standards for performance and reliability.

- With us your money in protected your business enterprise in secure.

- We offer a wide range of Tube Drawing Machines to cater to various industrial applications.

- We have a multicultural global network and a team that respects each other and encourages teamwork for development.

- We provide comprehensive product training and user manuals for our Tube Drawing Machines to ensure proper operation.

- We have won widespread praise from the market and customers, and we continues to expand its team.

- You can rely on us for high-quality Tube Drawing Machines that meet your production needs.

- The company implements a salary system combining basic salary, position salary and assessment salary, etc. The salary of employees grows year by year along with the company's efficiency, so that the value of talents is fairly rewarded.

Hot Tags: tube draw bench machine, China tube draw bench machine manufacturers, suppliers, factory, auto drawing machine, push pointer machine, rotary draw bender, tube bender, rotary draw tube bender, draw plate machine