Introduction:

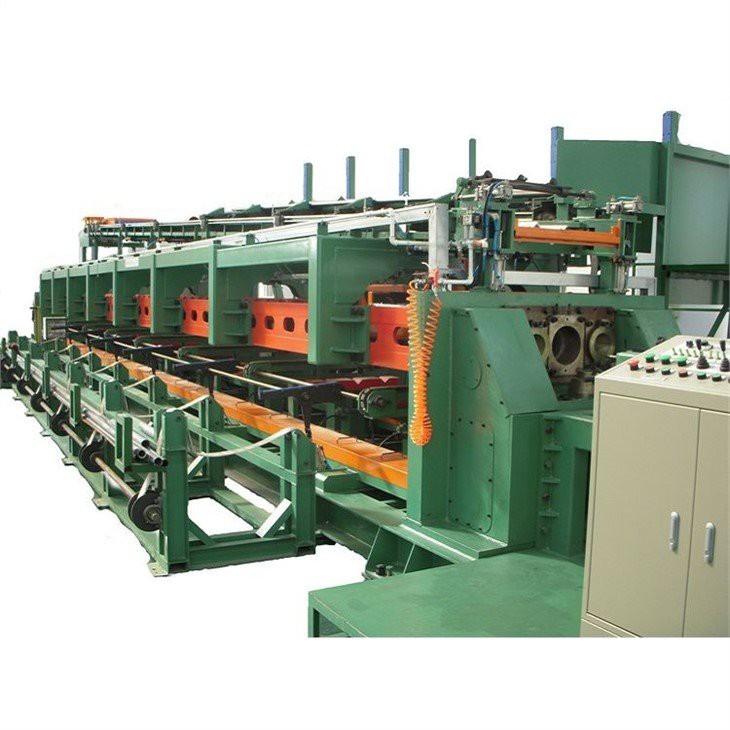

As one of the leading manufacturers in China, we take pride in producing high-quality industrial machinery for export to a range of countries worldwide. Our range of industrial machinery includes the highly efficient and reliable Seamless Pipe Drawing Machine, which is capable of producing seamless pipes with ease and precision.

Our Seamless Pipe Drawing Machine is designed to cater to the ever-increasing demand for quality pipes, which are used in various industries such as construction, oil and gas, and manufacturing. With our machine, merchants can produce pipes of different sizes, thickness, and shapes with ease.

Features and Benefits:

1. High Precision: Our Seamless Pipe Drawing Machine is designed to produce high-precision seamless pipes with a smooth finish. The machine is equipped with the latest technology in the industry, which ensures accuracy and reliability in the production process.

2. Easy to Operate: Our machine is designed to be user-friendly, making it easy for operators to set up and run. It comes with a touchpad control panel that makes it easy to adjust settings and monitor the production process.

3. Energy-efficient: Our Seamless Pipe Drawing Machine is designed to be energy-efficient, consuming less power during operation. This feature translates to lower energy bills and a more sustainable production process.

4. High Production Capacity: Our machine is designed to produce pipes in large quantities, making it an ideal option for manufacturers who need to produce a high volume of pipes quickly.

5. Versatile: Our machine is designed to produce pipes of different sizes, thickness, and shapes. It can produce pipes in a range of materials such as steel, stainless steel, copper, and aluminum.

6. Low Maintenance: Our machine is built to last, requiring minimal maintenance. The machine's minimal downtime ensures maximum productivity and reduces production costs.

Conclusion:

Our Seamless Pipe Drawing Machine is an excellent option for merchants who need reliable and efficient machinery to produce high-quality seamless pipes. Our machine's high precision, easy-to-operate features, and energy-efficient design make it an excellent investment for any manufacturer looking to produce quality pipes while keeping costs low.

We take pride in our product and guarantee its quality and reliability. With our machine, merchants can produce seamless pipes of different sizes and shapes, ensuring that they cater to the specific needs of their customers. Contact us today and take advantage of our reliable and efficient Seamless Pipe Drawing Machine.

Specification of Seamless Pipe Drawing Machine

|

Specification |

|

|

Model |

FR-150 THREE LINE DRAIWNG MACHINE |

|

Drawing manner |

3 line type; both sides drawing chain; middle discharging; |

|

Raw material tube diameter |

Max.ф100mm (Different material with different diameter range, it depend on the reduction.) |

|

Effective length |

Effective length 6m(the distance from carriage to Mold base) |

|

Core length |

Effective length 5m |

|

Drawing force |

20T |

|

Drawing speed |

0-15m/min |

|

Motor |

Host motor: 75kw DC speed regulator; |

|

Coupling |

Flange glue stick type coupling |

|

Power and voltage |

380V 50HZ |

|

Frame |

Front 25# H steel*4pcs; |

|

Chain |

Host chain:4020 heaving benching plate chain; |

|

Sprocket shaft |

Ф200mm |

|

Chain wheel |

18 teeth |

|

Mould/Dies basement |

120mm thickness |

|

Mould installation rack |

Ball type adjustable mould base |

|

Pipe receiver device |

Pneumatic cylinder lifts and falls to receive pipe; |

|

Pipe feeding device |

Automatic single pipe in |

|

Drawing trolley |

Pneumatic clamping (Clamping method |

|

Automatic rack |

Carrying capacity<2T; |

|

Raw material tube straightness required |

≤2mm/m |

|

Raw material tube inner diameter required |

≥18mm |

|

Drawing oil |

Pneumatic diaphragm oil pump; |

|

Mould/Dies |

Not including |

|

The equipment installation drawing is supplied after two parties’ agreement. The buyer supplies the power, air power, concrete foundation, chain lubrication oil, reducer oil, drawing oil. |

|

Description of Seamless Pipe Drawing Machine

The automatic drawing machine produced by our company is a chain-type drawing machine, which is suitable for precision machining of various metal materials; such as copper, iron, aluminum, stainless steel and other pipes and bars; according to different requirements of customers The drawing length and speed are designed, and there are single drawing and multiple drawing methods; and the models are relatively comprehensive, which can be selected by customers; using PLC full control, it can realize automatic feeding, piercing core pulling rods, and automatic oil supply inside and outside. Function; product performance is reliable, saving labor to the greatest extent for manufacturers and improving production efficiency.

CLIENT CASE

APPLICATION

Widely used in copiers, printers, rollers, sports equipment, furniture, aviation, automotive industry, electrical accessories, electronic products, medical equipment, machining.

PACKAGE&SHIPPING

Straightening Machines Packed in plastic films in container, electrical parts must be wrapped in a waterproof package in wooden case which not defected due to sea shipment.

PRODUCTION WORKSHOP

FOREIGN CLIENTS VISITING

Our products are very popular in China and abroad through unremitting efforts by FangRong people; the prime quality and best service are fully recognized and accepted by customers around the world.

FAQ

Q: When can I get the price?

A: Usually we quote within 24 hours after we get your inquiry.

Q: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Always 25-28days based on general order .

Q:What is your terms of delivery?

A:We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

Q: Can the products be manufactured by customer's requirement?

A: Yes, the specifications stated above are the standard ones, we can design and manufacture as requirement.

Q:How can I place an order?

A:You can contact any of our sales person for an order. Please provide the details of

your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, WECHAT or QQ or WhatsApp or other instant ways, in case of any delays.

Why choose us?

- Our Tube Drawing Machines are built with safety in mind, ensuring a secure operating environment.

- We are based on our own R&D system from the beginning to the end, and at the same time, we strive to learn from the advanced technology at home and abroad to develop high-quality Seamless Pipe Drawing Machine.

- We are committed to providing our customers with the best Tube Drawing Machines and services.

- We are committed to developing more individualized Seamless Pipe Drawing Machine and services, while ensuring that they are competitively priced.

- We prioritize customer satisfaction and strive to exceed your expectations with our Tube Drawing Machines and services.

- Our company always follows the principle of quality first and reputation first, with strong technical force, high technical level, advanced and strict process control, rich professional manufacturing experience, perfect quality assurance system, and zero-distance after-sales service, so that our customers get convenience.

- We provide comprehensive product training and user manuals for our Tube Drawing Machines to ensure proper operation.

- We provide our customers with better products and more perfect services to further consolidate the market position and customer confidence.

- We strive for excellence in everything we do, from manufacturing to customer service for our Tube Drawing Machines.

- We strive to achieve the corporate mission of "becoming a company loved by customers, trusted by shareholders, proud of employees and respected by rivals".

Hot Tags: seamless pipe drawing machine, China seamless pipe drawing machine manufacturers, suppliers, factory, rotary jewellery wire drawing machine, bar drawing machine, bending machine drawing, tube draw bench machine, mechanical drawing machine, tube bender drawing