The Bright Bar Drawing Machine is a state-of-the-art piece of equipment designed to meet the demands of modern-day manufacturing. As a manufacturer based in China, we have designed this machine to help our customers in various countries outside of China to improve their productivity and efficiency in the metalworking industry. The machine guarantees the highest quality finish of bright bar materials, simplifying the manufacturing process while also reducing production costs.

Attractive Features of the Bright Bar Drawing Machine:

High-Quality Finish:

The Bright Bar Drawing Machine is specifically designed to give your production line high-quality bright bars. By using the latest technology, our machine can produce bright bars with a smoother finish, a rounder shape even more precise dimensions. This gives our customers the quality they need to deliver the best to their end-users.

Improved Precision:

Precision is everything in the metalworking industry. The Bright Bar Drawing Machine is designed to achieve the highest levels of precision, measured to ultra-tight tolerances. Testing shows that the customer obtains precise dimensions after the 3rd pass, contributing to improved accuracy that transcends cut-throat competition.

Efficient Production:

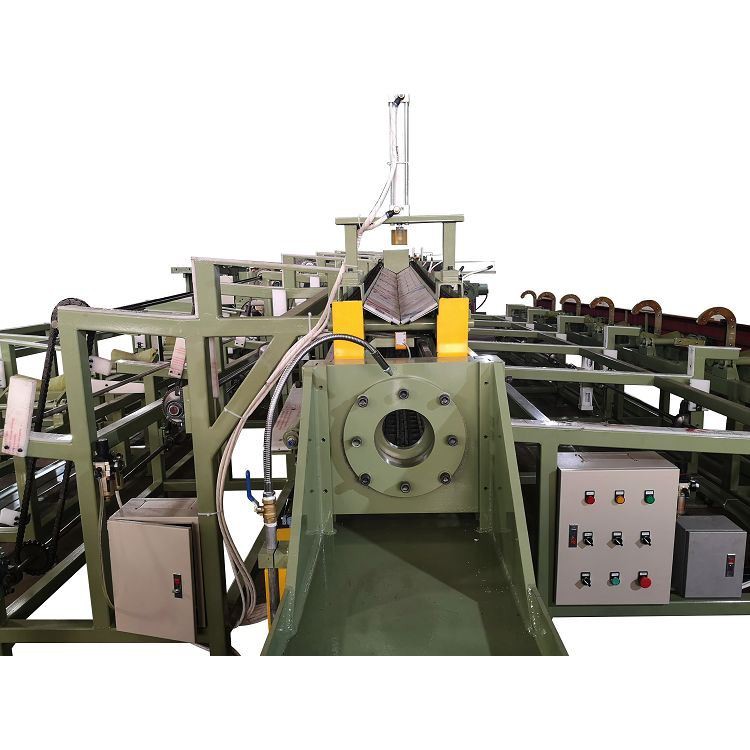

The Bright Bar Drawing Machine is equipped with a range of features that makes it unparalleled for efficient production. The machine adopts a one-piece frame and no-welding design, making it more rigid and enhancing stability, improving the reliability of the machine. This ensures that the machine can yield more than ten times better than conventional machines, enabling the customer to improve productivity and efficiency.

Reduced Operating Costs:

The Bright Bar Drawing Machine achieves increased efficiency while reducing operating costs at the same time. The machine features a state-of-the-art energy-saving system that reduces the energy consumed during operation. With a simple lock-up procedure, the machine is more energy-efficient and provides excellent efficiency per teary with affordable operating costs.

Easy Maintenance:

One of the main selling points of the Bright Bar Drawing Machine is how easy it is to maintain. The machine has an easy-to-use graphical interface, allowing the user to easily monitor the machine's every move, making maintenance easier to attend to whenever the machine requires it. The operator can also set maintenance reminders, ensuring that the machine is running at optimal efficiency at all times.

Conclusion:

In summary, the Bright Bar Drawing Machine has been designed to meet the demands of modern-day manufacturing, resulting in improved accuracy, efficiency, and cost-effectiveness. Our customers can expect reliable, high-quality bright bars with exceptional precision, enabling them to operate at top efficiency. With our machine, the customers can maintain a competitive edge in their working industries. Purchase Bright Bar Drawing Machine from us and be confident in the investment for it will definitely pay off.

Specification of Bright Bar Drawing Machine

Specification | |

Model | FR-10T Hydraulic Drawing Machine |

Drawing manner | one shape one set mould |

Raw material tube diameter | Tube: Max. OD Ф51mm* Max. WT3.5mm with 1 line type |

Effective length | 6m(the distance from carriage to Mold base) |

Core length | 5m(suit for outter diameter ≥ 5mm) |

Drawing force | 100KN(10Ton) |

Drawing speed | 3-20m/min |

Carriage speed | 25m/min |

Oil pump motor | 75kw-4P 50HZ |

Main oil cylinder | ¢150mm(piston rod: ¢80mm) |

Oil pump (vane pump) | VICKERS |

Preset pressure | 17Mpa |

Fuel tank capacity | 2800L+Oil tank |

Cooling oil pump | 50L |

Solenoid valve | YUKEN |

Main Frame | A3 plate, channel welded |

Carriage Rail | Linear Guid: HRL45CA |

Carriage | A3 plate, pneumatic clamping, slideway go and return movement |

Mould Installation base | A3 plate welding with ball type mould plate and bowl type adjustable base. |

Height of center | 800mm |

Pipe receiver | Arm |

Drawing oil manner | High-pressure, high-temperature oil pump, internal and external mold pumping oil at the same time (internal oil supply internal diameter above ф16mm, high drawing oil viscosity can't be used) |

Electrical control system | Omron; |

Action tracel control | Tracel switch, relay |

Working principle

The wire drawing machine is composed of a wire drawing part and a coiling part. The wire drawing part consists of a wire drawing wheel, a die holder and a die. After the wire passes through the die, it is wound on the wire drawing wheel. When the wire drawing wheel and the coiling wheel are running, the coiling wheel The operation provides the traction tension of the wire. Under the action of the traction tension, the wire is wound through the drawing wheel to make the wire pass through the wire drawing die, so that the wire is continuously changed from thick to thin, thereby obtaining wires of different wire gauges. Stretching, also known as die drawing, wire drawing, wire drawing, stretching, etc., refers to a process method of pressing metal materials through drawing dies at room temperature.

CLIENT CASE

APPLICATION

Widely used in sports equipment, furniture, automobile industry, electrical accessories, electronic products, medical equipment, machining.

Package

1. The hydraulic straightener is packed in a wooden case.

2. Neutral bags are also acceptable.

PRODUCTION WORKSHOP

FAQ

Q: When can I get the price?

A: Usually we quote within 24 hours after we get your inquiry.

Q: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Always 25-28days based on general order .

Q:What is your terms of delivery?

A:We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

Q: Can the products be manufactured by customer's requirement?

A: Yes, the specifications stated above are the standard ones, we can design and manufacture as requirement.

Q:How can I place an order?

A:You can contact any of our sales person for an order. Please provide the details of

your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, WECHAT or QQ or WhatsApp or other instant ways, in case of any delays.

Why choose us?

- At our factory, we use the best raw materials and advanced equipment to produce Bar Drawing Machines that are durable and efficient.

- We do our best to build resource-saving and environment-friendly enterprises and contribute to the sustainable development of society and human beings.

- As a leading Bar Drawing Machine manufacturer, we understand the importance of quality, performance, and reliability.

- We uphold the people-oriented concept, care for employees, attach great importance to the training and motivation of talents, and establish an excellent corporate culture.

- Our expertise in Bar Drawing Machine manufacturing enables us to produce machines that are fit for purpose and durable.

- Our products have won the trust and praise of our customers with premium quality and reasonable prices.

- We have a team of experienced engineers and technicians who ensure every Bar Drawing Machine we make meets the highest standards.

- Innovation is the first driving force for the development of enterprises, without innovation, there will be no future, and it will be eliminated by the market. Innovation is regardless of position and size, invention and creation is innovation, and creative problem solving is also innovation.

- Our factory is equipped with the latest technologies and tools to produce Bar Drawing Machines that meet the highest standards.

- With the increasingly fierce competition in the global market, the continuous development of new Bright Bar Drawing Machine to respond quickly to the market has become the core of market competition.

Hot Tags: bright bar drawing machine, China bright bar drawing machine manufacturers, suppliers, factory, metal rods cold drawing machine, draw tube bender, bright bar drawing machine, auto pipe drawing machine, industrial steel bar drawing machine, automatic tube draw bench machine