Introduction:

The Square Tube Straightening Machine is a highly efficient and reliable tool for straightening square tubes. It achieves precise straightening without damaging the surface of the tube. The machine is manufactured using high-quality materials and advanced technology, ensuring excellent performance and durability. The Square Tube Straightening Machine is used in various industrial applications, from construction to furniture manufacturing, and is essential for achieving a high-quality finished product.

Features:

1. Precise Straightening: The Square Tube Straightening Machine uses advanced technology to achieve precise straightening of square tubes. It ensures that the tube remains straight and without any damage to its surface. This is essential for achieving a high-quality end product.

2. Efficiency: With the square tube straightening machine, you can straighten multiple tubes simultaneously, saving time and increasing productivity. The machine is highly efficient and can handle square tubes of different sizes.

3. Durability: The Square Tube Straightening Machine is constructed using high-quality materials, making it sturdy and long-lasting. The machine is designed to withstand the wear and tear of heavy usage, making it ideal for industrial applications.

4. Easy to Use: The Square Tube Straightening Machine is easy to use and requires no special training. The machine comes with clear instructions, making it easy to operate and maintain.

5. Safety: The Square Tube Straightening Machine is designed with safety in mind. It has various safety features that protect the user from any harm during operation. The machine also complies with all industry safety standards.

Advantages:

1. Improved Efficiency: The Square Tube Straightening Machine can straighten square tubes in less time than conventional methods, improving productivity and efficiency.

2. Cost-Effective: By using the Square Tube Straightening Machine, you can eliminate the need for manual labor, reducing costs and increasing profits.

3. High-Quality Straightening: With the Square Tube Straightening Machine, you can achieve a high-quality straightening of square tubes, ensuring that your end product is of the highest standard.

4. Wide Range of Applications: The Square Tube Straightening Machine is suitable for various industrial applications, including construction, furniture manufacturing, and more.

5. Low Maintenance: The Square Tube Straightening Machine requires minimal maintenance, ensuring that it operates at peak performance without any downtime.

Conclusion:

The Square Tube Straightening Machine is a must-have tool for any industrial application that requires the precise straightening of square tubes. Its efficiency, ease of use, and durability make it a popular choice in the manufacturing industry. The machine provides a cost-effective solution to the straightening of square tubes, making it a valuable addition to any business. With its advanced technology and safety features, the Square Tube Straightening Machine is the ideal choice for achieving high-quality finished products.

Specification of Straightening Machine

Specification | |

Mould | one shape one set mould |

Straighten length | 1-15m |

Starighten rollers | 13 groups |

Reducer | ZQ350 |

Working speed | 0-45r/min≈24m/min |

Rollers Size | Ф175×105mm |

Mold | Including |

Dimension | 1960×950×1400mm |

Straighten side length | 20-50mm |

Straightness | ≤0.3mm/m |

Main motor power | 7.5 kw |

Supply voltage | 380V 50Hz |

Transmission Shaft | Ф55mm |

Center height | 980mm |

Weight(reference) | 2500KG |

Company introducing

Dongguan Fangrong Precision Machine Industry Co.,Ltd was established in 1999 ,which a professional manufacturer on drawing machine and straightening machine and thread rolling machine ect .Our company is a professional manufacturer that intergrates development,production and selling .Over the years ,Our goal is to making professional and class equipment ,excellent service and top-ranking innovation ,to achieve product specialization ,technical specialization,services professional and team .

Working principle of straightener

Stretch one end of the profile to be straightened into the middle of the two wheels, and drive the profile forward by the roller through the motor, multi-stage reduction pulley (variable frequency speed regulation) and chain double-sided transmission to complete the straightening of the straightened workpiece

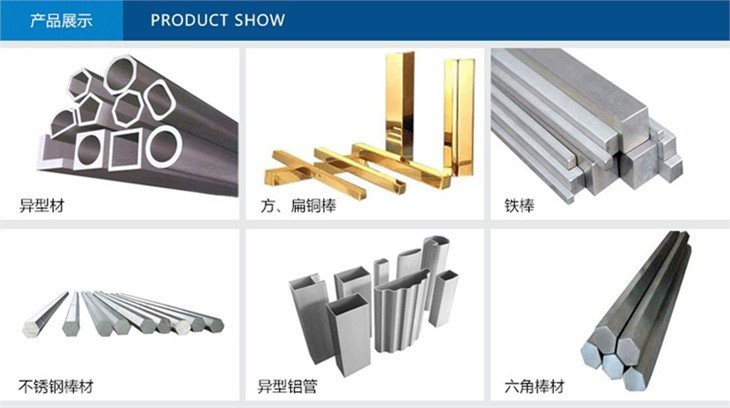

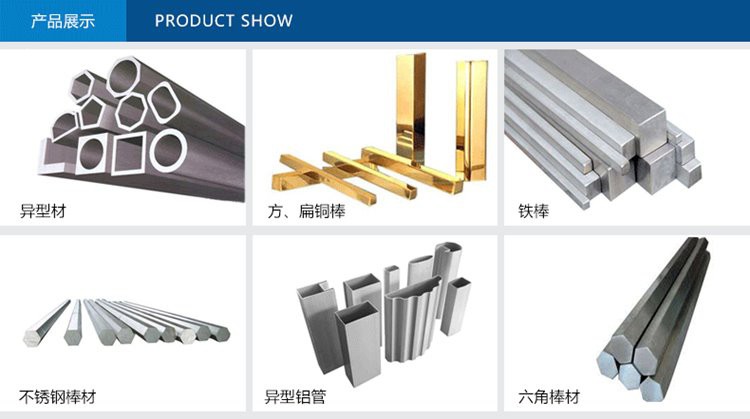

APPLICATION

Widely used in copiers, printers, rollers, sports equipment, furniture, aviation, automotive industry, electrical accessories, electronic products, medical equipment, machining.

CLIENT CASE

Bale:

1. The hydraulic straightener is packed in a wooden case.

2. Neutral bags are also acceptable.

PRODUCTION WORKSHOP

FOREIGN CLIENTS VISITING

Our products are very popular in China and abroad through unremitting efforts by FangRong people; the prime quality and best service are fully recognized and accepted by customers around the world.

CERTIFICATE

FAQ

Q: What’s your after-sale service?

A: Our quality warranty period is one year. Any quality problem will be solved to customer satisfactions.

Q: How can we get a quote?

A:Contact us with specification: such as material, design, size, shape, color, quantity, surface finishing, etc.

Q: QUALITY CONTROL?

A: We have QC person stay on the production lines do to the inspection.All products must have been inspected before delivery.we do inline inspection and final inspection.

1.All raw material checked once it arrive our factory.

2.All pieces and logo and all details checked during production.

3.All packing details checked during production.

4.All production quality and packing checked on final inspection after finished.

Q: Where is your factory located?

A: In Dongguan City, Guangdong Province China.

Why choose us?

- We work closely with customers to provide tailored solutions that meet their needs.

- We have to keep pace with the development of science and technology in terms of creativity in product design and development, production technology and manufacturing process of the Square Tube Straightening Machine.

- Our Tube Straightening Machines are highly durable and can withstand harsh industrial environments.

- After years of efforts, we have accumulated rich experience in R & D and production, and formed a set of mature production technology, which can provide domestic and foreign customers with high quality, outstanding performance and competitive price products in a timely, rapid, quality and quantity manner.

- Our Tube Straightening Machines are designed to meet the needs of customers around the world.

- Over the years, it is because of the common help of many partners in the same industry who share weal and woe that we have achieved today. We are glad to have many such partners!

- We have a professional team that ensures the performance and quality of our machines.

- 'Credit' has always represented our company's reputation in the market and has been recognized by our customers.

- Our machines are energy-efficient and environmentally friendly.

- We differentiate ourselves from the competition by optimizing costs while protecting the life cycle of strategic resources and promoting value creation.

Hot Tags: square tube straightening machine, China square tube straightening machine manufacturers, suppliers, factory, automatic scaffold tube straightening machine, channel straightening machine, pipe straightening machine, rebar straightener, straightener and roller machine, wheel straightening machine